Thursday, 28 September 2023

Tuesday, 26 September 2023

Sunday, 24 September 2023

ECM Wins 2023 IDEA Awards for its PrintStator Electric Motor CAD Software

ECM won the IDEA Awards’ Design and Operations Software category for its PrintStator Motor CAD platform.

The IDEA Awards also recognized ECM as an honoree in the Electric Motors, Drives and Components category for its ultra-light, premium efficiency, next generation, pump motor design created by PrintStator.

Hosted by Endeavor Business Media, the IDEA Awards celebrate outstanding innovation in product design and engineering. Finalists and winners are selected by the editorial teams of five publications and a readers’ choice vote by the engineering community of Machine Design, Electronic Design, Power & Motion, Microwaves & RF and Vision Systems Design.

“ECM is honored to receive recognition from the IDEA Awards’ editors and readers for our PrintStator Motor CAD software and integrated PCB Stator technology. Electric motor design and performance are in need of a 21st century makeover. PrintStator delivers that capability to the public via SaaS,” ECM CEO Brian Casey said.

The IDEA Awards distinctions underscore the dynamic benefits of ECM’s software offering and business model. As a company, ECM pairs PrintStator Motor CAD to patented PCB Stator innovation to create premium performance, next generation electric machines.

PCB Stators replace the bulky copper windings in traditional motors with an ultra-thin disc. PCB Stator motors designed via PrintStator are up to 70% lighter than conventional options, while achieving efficiencies in the mid-90s, and requiring just 20% of the raw materials.

As a SaaS design tool, PrintStator serves a critical market need while offering benefits to energy sustainability.

Macro trends—such as mass electrification and automation—are pushing global demand for specialized electric motors to over a billion units annually in a sector valued at over $200 billion.

On energy sustainability, research underscores that outdated electric motor systems account for over 40% of global electricity consumption.

These scenarios present a complex challenge: how to meet the supply needs of a world that demands over a billion specialized electric motors annually in a more sustainable way.

PrintStator delivers a product and technological solution in results and scalability.

As a software platform, PrintStator powers the custom design and manufacture of PCB Stator electric motors to precise performance and form factor requirements.

To scale these benefits broadly, PrintStator’s SaaS offering allows any electronics innovator—from startup entrepreneur to big-company engineer—to become an electric motor designer and producer.

ECM’s SaaS model extends options for vertical integration and production to large and small industry players alike.

About ECM

ECM PCB Stator Tech uses advanced Motor CAD and patented PCB Stator—printed circuit board—technology to create next generation electric motors for multiple applications. ECM’s PrintStator software powers the design, manufacture, and integration of PCB Stator electric motors that are lighter, quieter, more powerful, more energy and space efficient across a broad range of use cases. ECM designed motors achieve efficiencies in excess of 90 percent while requiring up to 70 percent less raw materials to produce.

ECM has partnered with multiple organizations to create optimized motor solutions across a variety of verticals: HVAC, Consumer Electronics, E-Mobility, Fitness, Medical, Robotics, Renewable Energy, Aerospace, Defense, and more.

ECM’s design partners include aerospace and defense innovator L3 Harris, global electronics manufacturer Celestica, and consumer electronics startup Nodo Film Systems.

ECM is a winner of four International SaaS Awards, including SaaS Solution of The Year, Best SaaS Product For CSR, Sustainability And ESG, and Best SaaS Product For Engineering Management, PLM Or CAD.

ECM’s electric motor design innovation has also received IDEA Awards and AHR Innovation Awards honors.

Visit:

Friday, 22 September 2023

Wednesday, 20 September 2023

Leveraging computational fluid dynamics in heat sink designs

In the realm of electronics design, heat sinks are essential devices that help to dissipate heat produced by electronic or mechanical devices. These thermal management devices play a pivotal role in the performance and longevity of electronic devices by preventing overheating.

Designing an effective heat sink, however, presents its own set of challenges. There are several variables at play, such as the shape and material of the heat sink and the airflow conditions, among other things. Finding the optimal combination of these variables to improve the heat sink’s performance is easier said than done. For instance, creating and testing new heat sink prototypes can be time-consuming and resource intensive.

Computational fluid dynamics (CFD) tools have become especially relevant in designing heat sinks, primarily because of their ability to model complex fluid and heat transfer scenarios, which are integral to effective heat sink design.

CFD: A quick primer

CFD is a branch of fluid mechanics that uses numerical methods and algorithms to solve, analyze and simulate engineering problems involving fluid flow and heat transfer. CFD tools rely on a set of fundamental differential equations called the Navier-Stokes equations, which are based on the principles of conservation of momentum and conservation of mass. These equations are combined with the conservation of energy equations to provide a complete mathematical model and description of fluid flow.

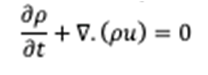

1. Conservation of mass (or the continuity equation)

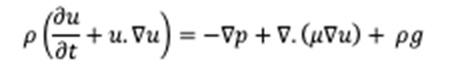

2. The conservation of momentum

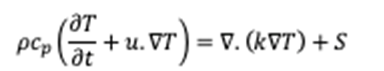

3. Conservation of energy

Where ![]() is the fluid density, u is the velocity vector,

is the fluid density, u is the velocity vector, ![]() is the pressure,

is the pressure, ![]() is the dynamic viscosity, g is the acceleration due to gravity, cp is the specific heat at constant pressure, T is the temperature, k is the thermal conductivity and S is the volumetric heat source.

is the dynamic viscosity, g is the acceleration due to gravity, cp is the specific heat at constant pressure, T is the temperature, k is the thermal conductivity and S is the volumetric heat source.

Learn more: Introduction to computational fluid dynamics

CFD in heat sink design

By applying CFD to heat sink design, engineers can gain valuable insights into air velocity, temperature distributions, pressure drops and heat transfer coefficients. In addition, CFD provides valuable information about thermal resistance and pressure drop, all of which are valuable for optimizing heat sink performance.

Visit:

Tuesday, 19 September 2023

Monday, 11 September 2023

Prospects in mechanical engineering

What Others Are Reading See More Nature journalling, a powerful learning tool Gati Shakti University, Airbus ink pact to train students for aviation sector With guidelines for students with special needs, UGC eyes more inclusivity in higher educat...

Here are a few fields where mechanical engineering continues to be relevant. Biomedical and Pharmaceutical industry: Most of the cutting-edge technology used in the pharmaceutical industry are developed with the involvement of mechanical engineers, ...

Biomedical and Pharmaceutical industry: Most of the cutting-edge technology used in the pharmaceutical industry are developed with the involvement of mechanical engineers, especially those with knowledge in design and manufacturing.

Even a company manufacturing something basic, like disposable syringes, needs a machine that moulds medical grade plastic into a syringe. The regular maintenance of these machines also requires the skill set of mechanical engineer.

The regular maintenance of these machines also requires the skill set of mechanical engineer.

Food industry: The food processing industry has seen a heavy shift towards automation, which has taken place on the back of machines. This starts from the manufacture of food processing machines used, and involves other subjects like Automation, Rob...

Visit:

International Conference on Computer Aided Design in Mechanical Engineering

Nomination Link: https://x-i.me/cad02ja

#DefenseCAD #MilitaryDesign #CADforSecurity #WarfareTechCAD

Social media Link:

YouTube: youtube.com/channel/UCGpONJQzsHCByPoa1ZeCPnA

Instagram: instagram.com/sophiaisabella270/

Twitter: twitter.com/sophiai14453133

LinkedIn: linkedin.com/in/sophia-isbella-1b63b6260/

Blogger: mechanicscience.blogspot.com/

5 Workflow Automation Tools for All Professionals

Automation can benefit professionals across various fields, including project managers, analysts, and solo founders. We all face repetitiv...

-

CNC MACHINING CNC 101: The term CNC stands for 'computer numerical control', and the CNC machining definition is that it is a su...

-

Gears play a critical role in mechanical engineering, serving as essential components in various machines and mechanisms to transmit power...

-

Optical MEMS technology integrates mechanical elements, electronics, and sensors on a silicon substrate through microfabrication, enabling...